Mission Critical: Tethered Power Systems for Restricted Airspace

A leading Singaporean industrial drone provider (name confidential) has redesigned its power supply units for specialized operations requiring:

✅ Hazard Zone Surveillance: Chemical plants/power grids with strict altitude limits (≤15m flight ceiling)

✅ Continuous Power Delivery: 7m armored cables enabling 72hr+ UAV operations

✅ Extreme Environment Resilience: Withstanding 95% humidity, L3 salt spray, and -20°C to 60°C thermal shocks

The legacy mini XLR connectors presented critical failures:

⚠️ Frequent disconnections under vibration (average 3.2min failure @200Hz)

⚠️ 4min15sec swap time with safety gear

⚠️ 18% contact resistance fluctuation in humid conditions

Engineering Revolution: Push-Pull Locking Connector Advantages

▍Performance Comparison

| Metric | Legacy mini XLR | Push-Pull Connector |

|---|---|---|

| Connection Speed | 22s (threaded) | 0.8s |

| Vibration Resistance | MIL-STD-810G Cat | Cat7+ |

| IP Rating | IP54 | IP68/IP69K Dual-Certified |

| Temperature Range | -10°C~50°C | -40°C~125°C |

| Mating Cycles | 1,500 | 10,000+ |

▍Specialized Design Features

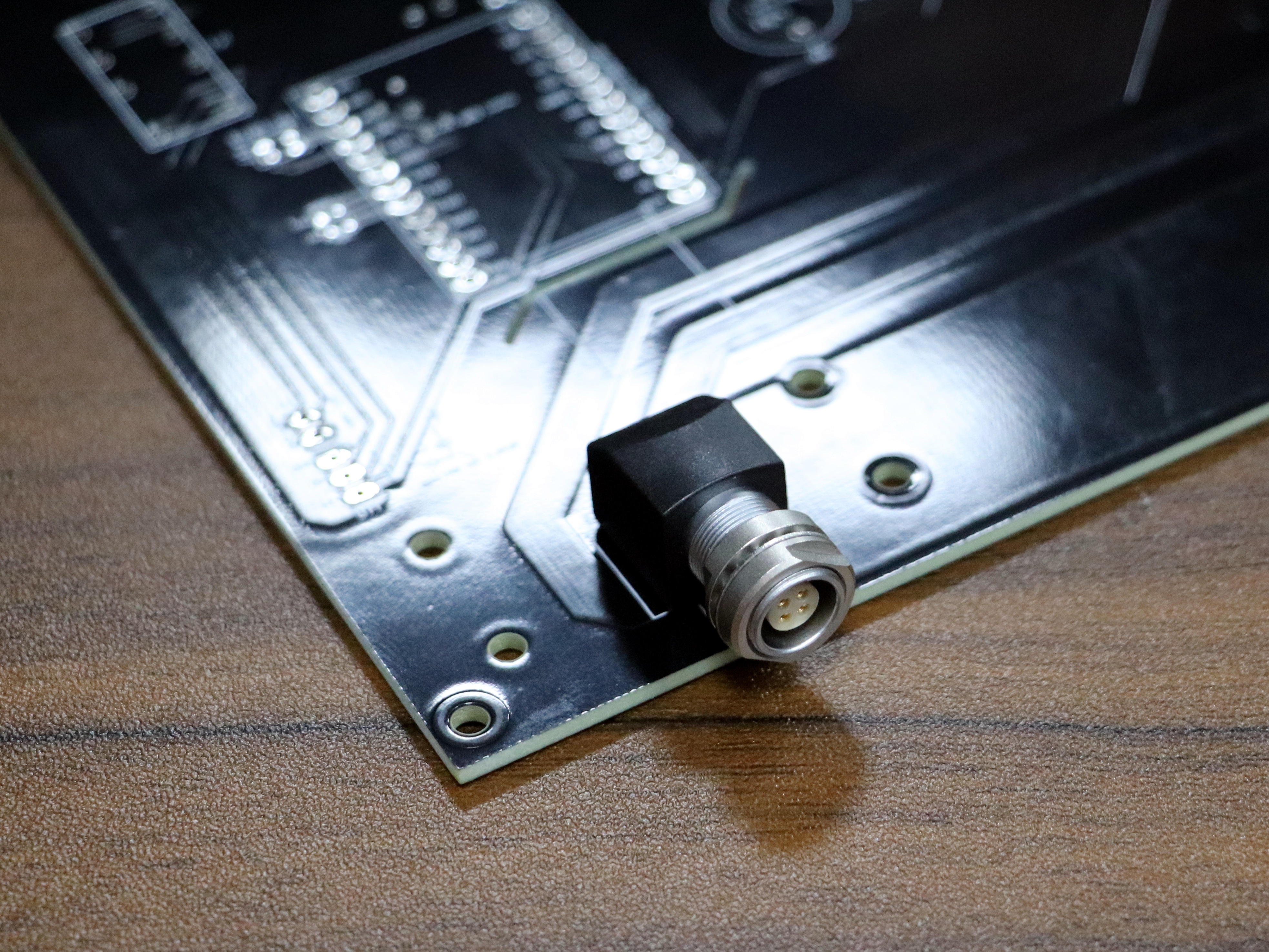

Intuitive Locking Mechanism

Tri-stage tactile/audible feedback (85dB @10cm at full engagement)

45N+ retention force with angle-specific release to prevent accidental disconnects

Environmental Sealing

Dual silicone O-rings + hydrophobic nanocoatings (contact angle >150°)

Validated at 5m depth pressure for 72hr

Power Transmission Upgrade

0.8μm gold plating stabilizes contact resistance at 0.8mΩ±0.1

Integrated overcurrent protection (3ms response time)

Field Validation: Operational Excellence Achieved

Client testing demonstrated transformative results:

Deployment Speed: System setup reduced from 8min → 2min15sec

Stability: Operational interruptions decreased by 97% (3.2→0.1/hr)

Maintenance Costs: Connector-related repairs cut by 83%

Case Study: Oil Refinery Tank Inspection

Tethered drones equipped with new connectors achieved:

🔹 6hr continuous flights (previously 4hr max)

🔹 99.98% data integrity (vs 97.3% legacy)

🔹 0.15sec emergency cutoff (beating 0.5sec industry standard)

Technical Q&A Deep Dive

Q: How ensure reliability in oily environments?

A: Our patented wiping-contact design (Patent: CN2023XXXXXX) self-cleans during mating cycles, combined with fluorocarbon seals, maintains performance in API Class III oil mist.

Q: Solutions for cable torsion?

A: Integrated 360° anti-twist mechanism withstands 5N·m torque through 200k rotations, allowing ±180° free movement.

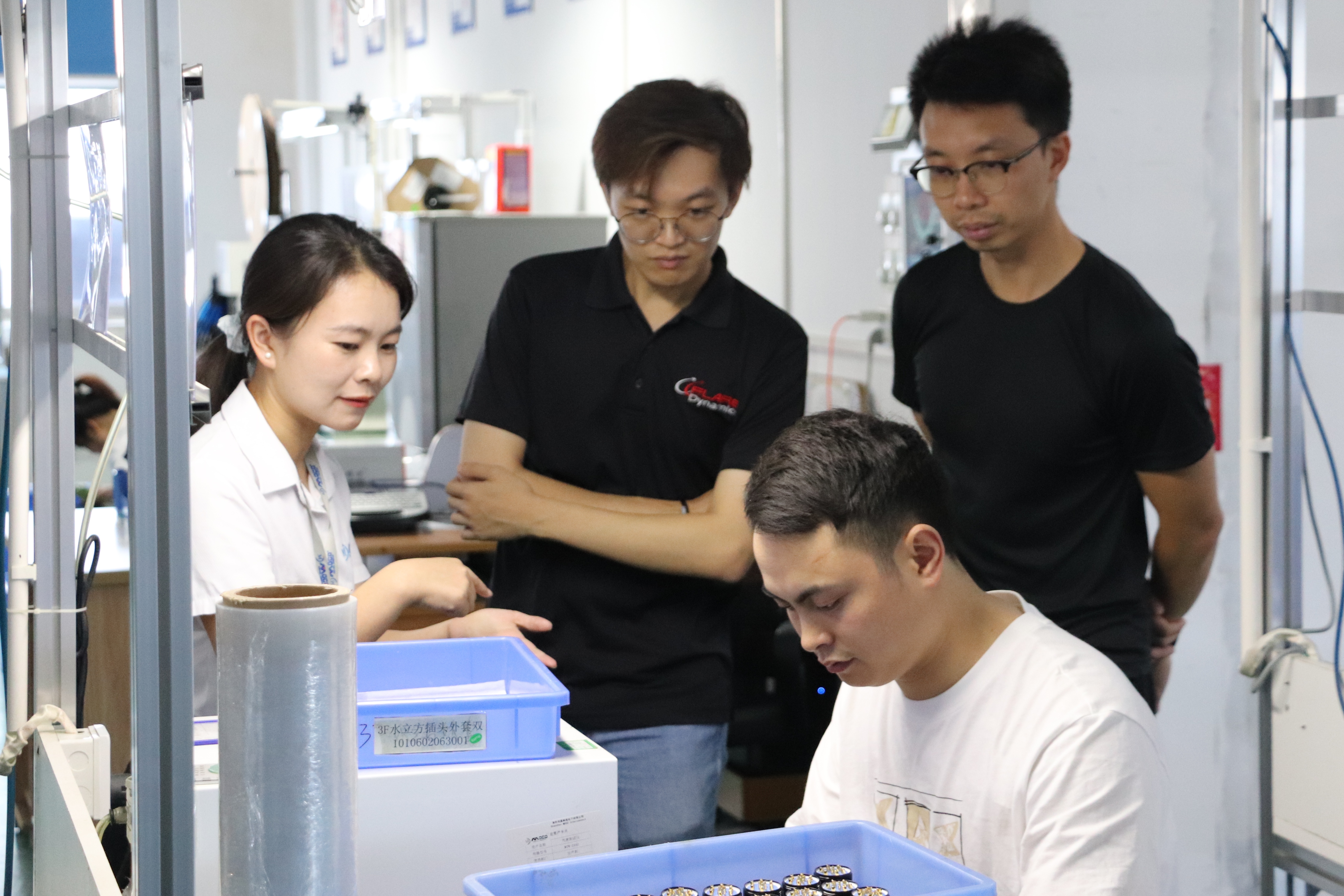

1.Precision Machining Center

Witnessed CNC-controlled production of connector housings (±5μm tolerance)

Operated under ISO Class 7 cleanroom conditions

Real-time process monitoring via 56 IoT sensors per production line

2. Environmental Simulation Lab

Demonstrated connector endurance testing:

95% humidity chamber cycling (MIL-STD-810H Method507.6)

20G vibration stress screening (DO-160 Section 8.0)

Reviewed salt spray test specimens after 1,000hr exposure

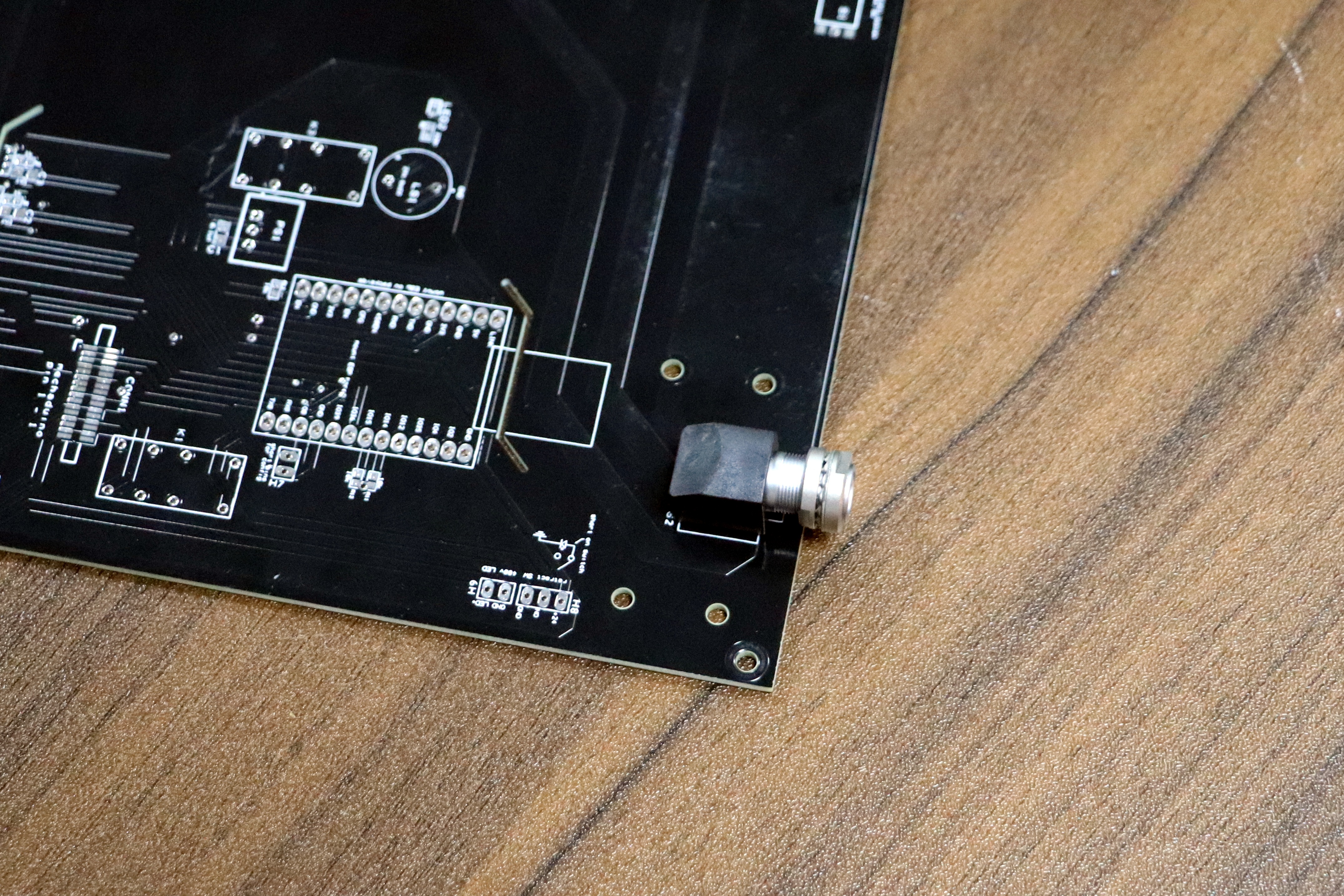

3. Custom Assembly Zone

Showcased client-specific configurations:

Oil-resistant cable assemblies undergoing 360° rotation testing

Military-grade potting process for waterproof connectors

Presented live demo of push-pull connector mating (<1sec engagement)