Professional Material requirements for M12 connectors manufacturers

For customers, when buying M12 connector products, one of the issues they are more concerned about is the quality of M12 connector products. When it comes to the product quality of M12 connectors, we have to pay attention to its product material, because the choice of raw materials is directly related to the performance of the product, so what are the material requirements of M12 connectors?

Contact us now. Best regards!

With the rise of electronic technology, more and more electronic devices need to use connector products, which makes our life more convenient, but the quality of the new product is also facing a serious test. With the trend of smaller and smaller connectors, the material of M12 connectors is undoubtedly a great challenge! So what are the specific material requirements for M12 connectors?

1, the mechanical properties of the M12 connector material requires that the connector must have a certain degree of strength and stiffness, because it is necessary to fix the terminals. Later, the swing test, impact test and other tests will be carried out to detect the quality of new products, so there should be a certain degree of toughness;

2, M12 connector material thermal performance requirements due to the late lead-free soldering process, the temperature is about 260 degrees, time about 15s, so the connector material must have high temperature resistance, that is Short-term thermal index HDT must meet the conditions. Long-term use temperature (RTI index) does not need to be too high, depending on the function of the connector;

3. The electrical energy of the M12 connector material requires that all plastic parts of the connector are insulated. High-frequency products may have certain requirements for dielectric constant and loss factor, and some shell and bracket products also need to have anti-static requirements;

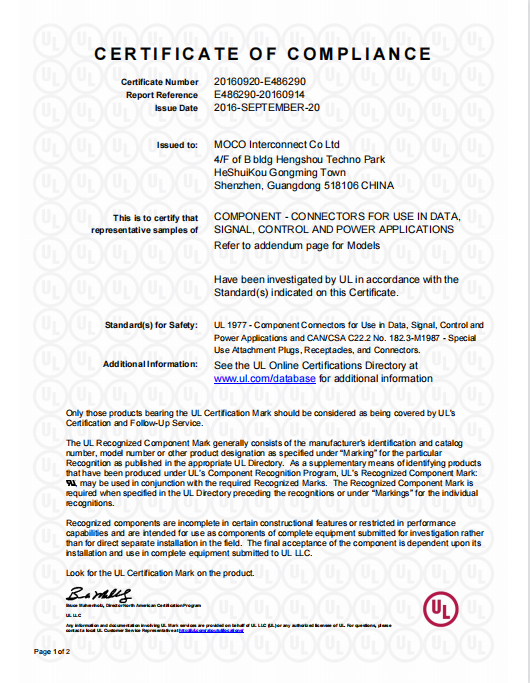

4, M12 connector materials flame retardant environmental requirements require connector materials for most products with flame retardant basically in line with UL94V0. In the trend of environmental protection, most of the pursuit of halogen-free, but currently halogen-free halogen-free about half;

5, M12 connector material physical and chemical performance requirements due to the connector needs to be solder paste contact, salt spray test, as well as some customer requirements, connector materials must have certain chemical properties. For I / O appearance products, in addition to low water absorption and dimensional stability, but also requires UV resistance;

6, the appearance of M12 connector materials and dyeing requirements of the current connector either in the motherboard or other parts of the need for a variety of colour requirements, so the connector material must have good dyeing properties, and in the case of high temperatures also have a good colour stability is good, not easy to fade;

7, M12 connector material processing requirements processing performance. Because the connector industry has low profits and many mould cavities. Therefore, the connector material needs to have a wide processing window, low die scale and low corrosion. Reduce downtime losses. Some products also require high flatness and low warpage.

Contact us now. Best regard!

Product Introduction

Product Information

Company Advantages

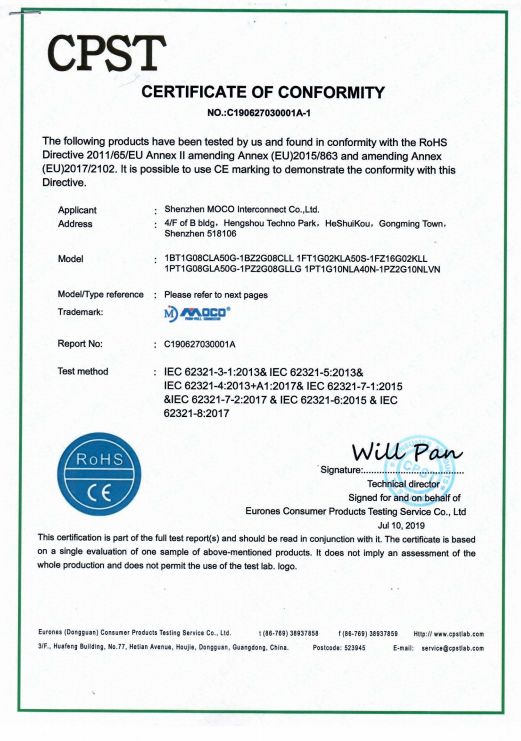

Certifications and Patents

Frequently Asked Questions about cctv cable manufacturer

PRODUCTS

QUICK LINKS

If you have any question, please contact MOCO connectors.

TEL: +86 -134 1096 6347

WhatsApp: 86-13686431391

EMAIL: eric@mocosz.com

2/F 1st Block,XinHao Industrial Park,N.O 21 XinWei Rd,XinZhuang Community,MaTian, GuangMing District,Shenzhen,P.R.C