The Essential Role of High-Performance Cables in Non-Destructive Testing Applications

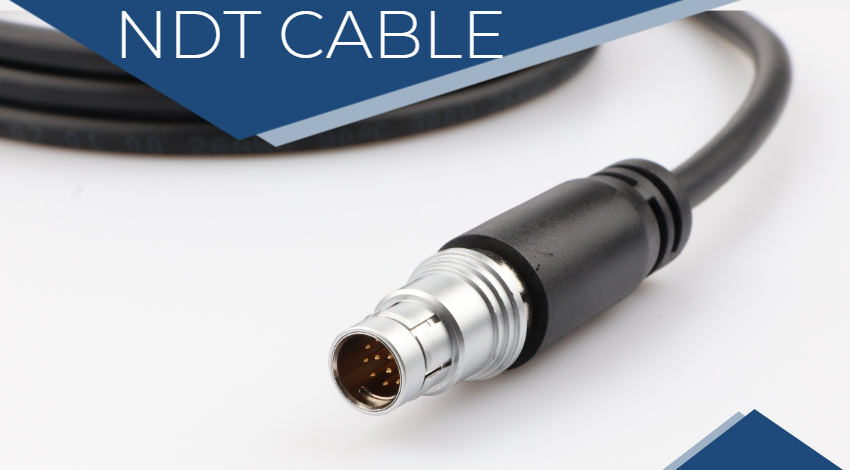

NDT cables are a crucial component in non-destructive testing applications, offering outstanding durability, accuracy, and cost-effectiveness. Designed to withstand the most challenging operating conditions, they provide highly precise and accurate data to engineers and technicians, ensuring any issues or faults are quickly detected and resolved. By using NDT technology to detect defects and flaws in materials and components, businesses can achieve long-term cost savings by avoiding expensive and time-consuming repairs or replacements.

NDT cables, or non-destructive testing cables, are a type of high-performance cable that are designed to meet the rigorous demands of non-destructive testing applications. These cables are commonly used in industries such as aerospace, automotive, and construction to conduct comprehensive testing on critical components, ensuring the highest level of safety and structural integrity.

One of the key features of NDT cables is their exceptional reliability and durability. These cables are engineered to withstand harsh operating conditions, including extreme temperatures, moisture, and corrosive environments. This ensures that they can perform optimally, even in the most challenging conditions.

Another advantage of NDT cables is the high level of accuracy they provide. Non-destructive testing techniques are designed to detect even the smallest flaws and defects in a material or component, and NDT cables are an essential component of this process. These cables provide highly precise and accurate data to engineers and technicians, ensuring that any issues or problems are quickly identified and addressed.

In addition to their reliability and accuracy, NDT cables offer significant cost savings over the long term. By using NDT techniques to detect flaws and defects in materials and components, companies can identify issues before they become serious problems, avoiding costly and time-consuming repairs or replacements down the line.

Overall, NDT cables are an essential component of non-destructive testing applications and are relied upon by some of the world’s most innovative companies. Thanks to their exceptional durability, accuracy, and cost-effectiveness, they are an excellent choice for any organization seeking to ensure the highest level of safety and quality in its products and processes.

- SurnameEric Wu

- Company NameShenzhen MOCO Interconnect Co., Ltd.

- E-maileric@mocosz.com

- TEL+86 136 1096 6347

PRODUCTS

QUICK LINKS

If you have any question, please contact MOCO connectors.

TEL: +86 -134 1096 6347

WhatsApp: 86-13686431391

EMAIL: eric@mocosz.com

2/F 1st Block,XinHao Industrial Park,N.O 21 XinWei Rd,XinZhuang Community,MaTian, GuangMing District,Shenzhen,P.R.C