Intro to Do I need heat shrink tubing for my BNC adapter? MOCO connectors

The world of electronics can be a difficult one to navigate, with countless components and connectors to choose from. When dealing with BNC adapters, one may wonder if heat shrink is a necessary addition to the setup. In this article, we’ll explore the ins and outs of BNC adapters, the role of heat shrink tubing, and how to determine if your specific application requires it.

What are BNC adapters?

Quick Overview

BNC (Bayonet Neill-Concelman) adapters are coaxial connectors that are commonly used to transmit radio frequency signals in a variety of applications, such as video surveillance, radio antennas, and test equipment. Their design includes a bayonet-style coupling mechanism that allows for an easy and secure connection.

Types of BNC Adapters

There are a variety of BNC adapters available to suit different applications. Some common types include:

BNC to SMA Adapter: Connects a BNC-equipped device to an SMA (Subminiature Version A) connector.

BNC to N Adapter: Allows an N-type connector to be connected to a BNC-equipped device.

BNC T-Adapter: Features a T-shaped design that allows multiple devices to be connected to a single BNC-equipped device.

BNC Coupler: Connects two BNC cables together, extending their length.

Heat Shrink Tubing 101

What Heat Shrink Tubing Does

Heat shrink tubing is a versatile material made of thermoplastic that shrinks when heated to form a tight, protective seal around cables, wires, connectors, and other electronic components. Its primary functions include:

Insulation: Protects electrical components from heat, moisture, and other environmental factors.

Strain Relief: Reduces stress on cable connections, preventing damage and disconnections.

Color Coding: Helps identify and organize cables and connections.

Aesthetic Appeal: Provides a clean, professional look to electronic installations.

How to Use Heat Shrink Tubing

Using heat shrink tubing is a breeze, even for those who aren’t experts in the field. Simply follow these steps:

Cut the tubing to the desired length, making sure it encompasses the entire area you wish to protect.

Slide the tubing over the cable, wire, or connector.

Use a heat gun, hair dryer, or lighter to apply even heat, being careful not to overheat and damage the tubing or components.

Let the tubing cool and inspect the end result for a secure fit.

Do BNC adapters require heat shrink tubing?

Now that we’ve covered the basics of BNC adapters and heat shrink tubing, let’s tackle the million-dollar question: Do BNC adapters require heat shrink tubing?

When Heat Shrink Is Required

There are certain situations where heat shrink tubing can be very useful for BNC adapters. Consider using heat shrink tubing in the following situations:

Outdoor Installations: Heat shrink tubing can provide an extra layer of protection for BNC adapters used in outdoor environments due to potential exposure to moisture, dust, and temperature fluctuations.

High-Traffic Areas: In environments where cables and connectors are frequently handled or moved, heat shrink tubing can provide strain relief and extra durability.

Organizational Tendency: If you're dealing with a large number of cables and connections, heat shrink tubing can help with color coding and organization, making maintenance and troubleshooting a breeze.

When Heat Shrink Is Optional

While heat shrink tubing can have advantages in specific situations, BNC adapters aren't always necessary. In indoor installations where environmental factors are minimal and the potential for cable movement is low, heat shrink tubing may not be necessary.

To Shrink or Not to Shrink?

Ultimately, whether or not to use heat shrink tubing for BNC adapters comes down to your specific application and the factors at play. By considering the environment, potential hazards, and organizational needs, you can make an informed decision on whether or not to employ heat shrink.

In short, it's best to err on the side of caution and use heat shrink tubing to protect your BNC adapters when in doubt. After all, a little extra protection never hurt anyone, right?

Best wishes, contact us now!

Product Introduction

Product Information

Company Advantages

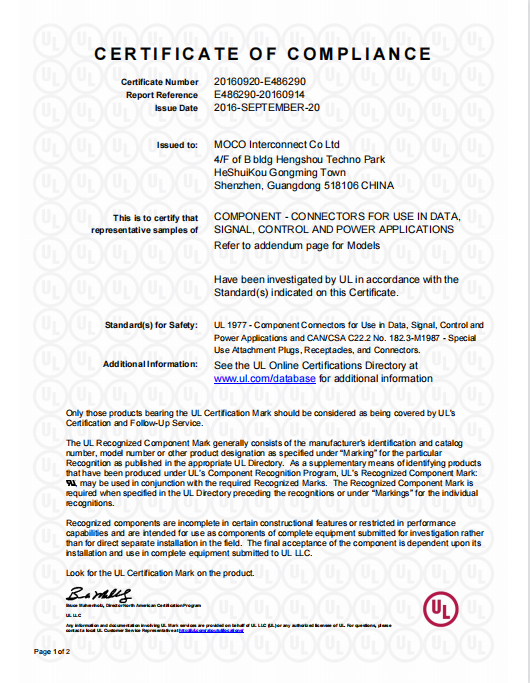

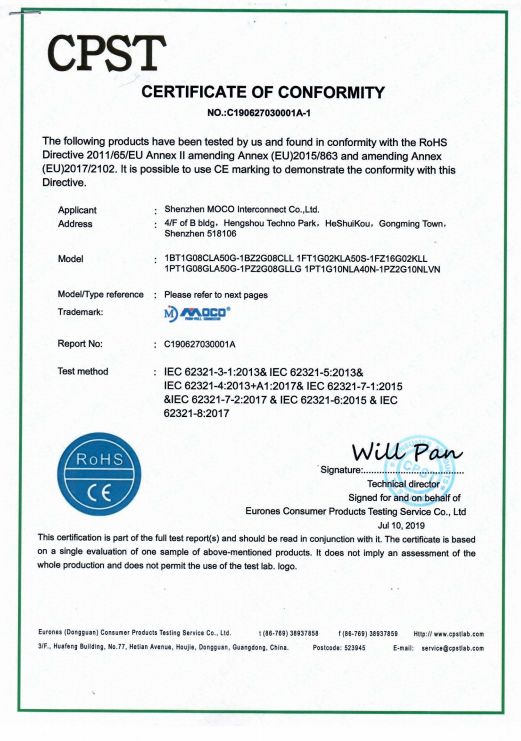

Certifications and Patents

Frequently Asked Questions about fiber cable manufacturers

PRODUCTS

QUICK LINKS

If you have any question, please contact MOCO connectors.

TEL: +86 -134 1096 6347

WhatsApp: 86-13686431391

EMAIL: eric@mocosz.com

2/F 1st Block,XinHao Industrial Park,N.O 21 XinWei Rd,XinZhuang Community,MaTian, GuangMing District,Shenzhen,P.R.C