You should finalize the type of connector at the early design stage of the developmental process as if the connector is selected after the completion of the design stage then it often reports compatibility issues.

Do you have any experience buying medical connector before? If not, then you should have a look at the following factors and consider them seriously whenever you plan to buy medical connectors.

The first thing to decide on is whether you want to use an identical connector with fixed keys that are integral parts of the connector’s body or a connector with customizable keys.

In case you want to go for a cost-effective option and are interested in decreasing the inventory cost, then you should select the connector with customizable keys.

In the case of medical devices with critical safety concerns, special care should be taken to guarantee that the receptacle and plug are interconnected accurately.

In some cases, connectors installed in patient’s monitoring equipment are mated and unmated frequently in a day during the lifetime of the connector. Therefore, in that case, you should confirm whether the connector can bear a repeated cycle of mating and unmating.

Generally, connectors must be able to bear 10’s of 1000’s of mating cycles and this number may vary depending on the nature of medical equipment.

Cleaning and sterilization are inevitable processes in the medical environment, as all equipment has to be sterilized before and after using them, therefore, you should ensure that the chosen connector can withstand mild detergent solutions while cleaning and high temperature during autoclaving and sterilizing.

In a medical environment, the majority of equipment is handled with surgical gloves, therefore, you should select the connectors that can be easily handled with surgical gloves without tearing and damaging them.

As the damage or tearing of surgical gloves may lead to the spread of infections or diseases, therefore, select the connector by keeping these concerns in mind.

Degree of Vibration and Shock

Another important factor is the degree of vibration and shock in the environment where the connector has to be used. For instance, if you are interested in using a connector in the ambulance then you should confirm whether the chosen connector’ design functions uninterruptedly in this environment or not.

Reliability is the most important factor to consider as you should finalize a connector that can perform perfectly in varying conditions over a long time.

To ensure reliability, you should prefer a connector with an alternate design instead of connectors with a conventional design which may wear out with time. For example, connectors with a hyperboloid contact system are one of the reliable options as they enable the insertion of connectors with low force, offering improved reliability.

MOCO Connectors has been manufacturing reliable and high-quality connectors for more than 12 years. Having a team of more than 500 professional experts and manufacturers, the company manufactures connectors that ensure high performance across varying industries including military, medical, NDT, robotics, rail traffic, and automation industry.

You must be wondering why choose MOCO Connectors for the medical industry, then here are some valid reasons for preferring it over other medical connector manufacturers.

1. Offer power and reliable connectedness

2. Durable and reliable

3. Easily handlable with surgery gloves

4. Designed to operate efficiently in tough environmental conditions

5. Affordable

Are you interested to know more about custom medical connectors offered by MOCO Connectors? Keep reading.

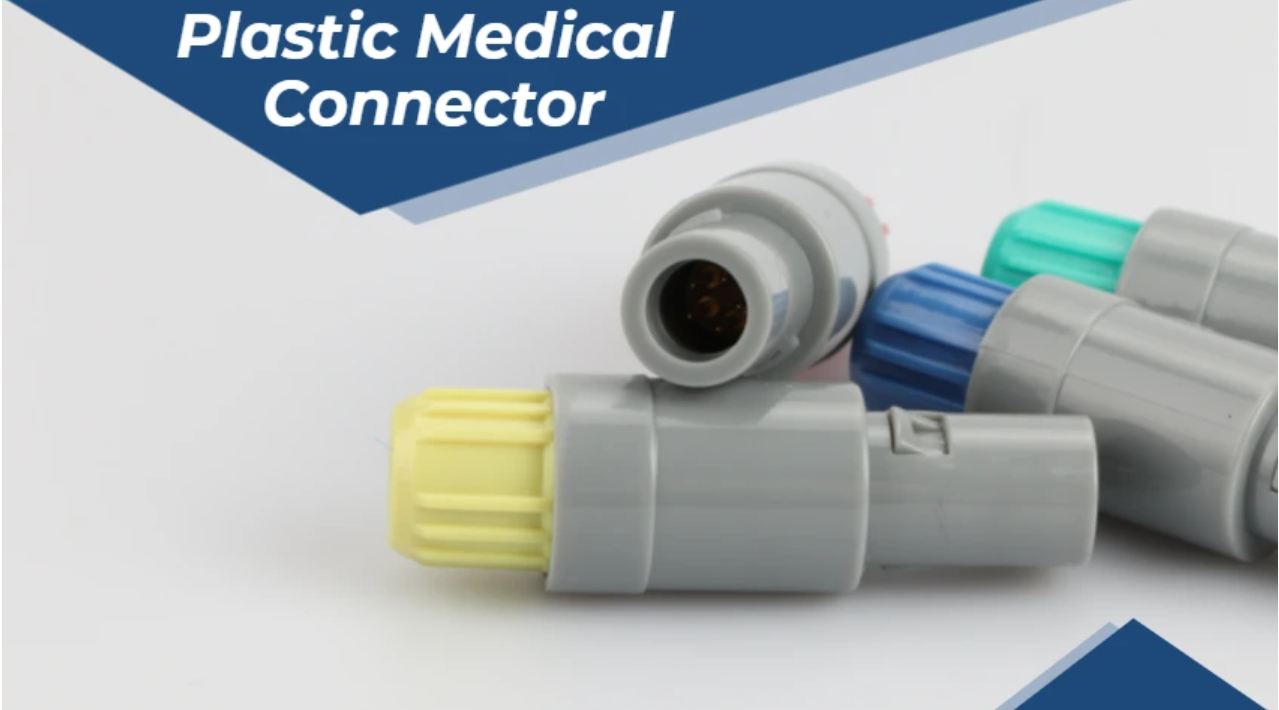

MOCO offers a wide range of medical connectors ranging from P-series plastic connectors, and B-series multipole connectors to NIBP metal connectors, and hybrid gas-electric connectors.

The P-series do not have any compatibility issues and are coherent with PFG, PAG, PLG, PNG, and PKG connectors. These connectors are also available in different colors so you can choose the one that suits your equipment.

MOCO medical connectors are workable in various medical equipment including Holter recorders, Endoscopy, Transcranial Doppler ultrasound Systems, Magnetic resonance imaging, Electrosurgical devices, Masimo Spo2, Beauty therapy systems, and electroporation systems.

Let’s see which is the best medical connector by MOCO.

Medical connectors plastic by MOCO Connector is one of the best and the most widely used medical connectors. It is made of high-quality plastic material that fulfills all standards to operate in the medical environment.

Additionally, using this connector in the medical environment offers the following benefits

Compatibility: It is compatible with a wide range of medical devices and equipment

Compliance: Ensured compliance with ISO9001:2015, CE, UL, GJB9001C-2017, and RoHS certifications.

Flexibility: The universal model of this medical connector is always available in stock and will be delivered at the fastest speed.

Professionalism: The 10 years of experience, research and development, and professionalism ensure high performance across all equipment.

In conclusion, the operation of medical device connectors and equipment requires strict standards and regulations to comply with, therefore, you should select medical connectors after meticulous research and rely on reliable medical connector manufacturers.

MOCO Connectors with its years of experience and diverse range of products is the best medical connector manufacturer in this regard on which you can rely confidently and you will never regret your decision.