Have you ever blamed your spotty Wi-Fi or fuzzy TV picture on the cable guy? Sometimes, the real culprit is much smaller: the connector at the end of the cable. Using the wrong type or a poorly attached one can seriously mess with signal quality. We're pulling back the curtain on coaxial connectors.

At its core, a coaxial connector acts as the crucial bridge. It physically links your coaxial cable – that familiar round wire carrying TV, internet, or radio signals – to your equipment. Think TVs, modems, routers, antennas, or testing gear. Without that connection point, the signal just stops dead.

But it's so much more than just a physical link. Coaxial cables carry high-frequency signals that are quite sensitive. The connector’s job is to maintain the signal’s integrity as it passes from the cable to the device. This means two key things:

1. Shielding Continuity: The connector continues the cable's protective shield. This barrier blocks outside electrical noise, known as interference, from corrupting the signal. Noisy signals mean poor performance.

2. Impedance Matching: Coaxial systems operate at a specific impedance (like 50 or 75 Ohms). The connector must match this impedance. Mismatches cause signal reflections, where part of the signal bounces back, weakening the main transmission.

Quality connectors, like those from Moco Connectors, are engineered precisely for these tasks. They ensure a secure fit and maintain that critical, interference-free signal path. Get this right, and your signal flows smoothly. Get it wrong, and you invite problems.

If you boil it down, the prime directive of any coaxial connector is this: transfer the signal between the cable and the equipment reliably. Every single time. This means passing that high-frequency signal along with the least possible amount of loss or added distortion.

Why is this the main job? Because everything else depends on it. Your sharp HD picture, your fast download speeds, your clear radio transmission – none of it happens if the connector fails at this basic task. It needs to hand off the signal perfectly.

This reliability has two sides:

1. Electrical Reliability: As we touched on, the connector must maintain the signal's integrity. It continues the shielding and keeps the impedance matched. This prevents signal degradation.

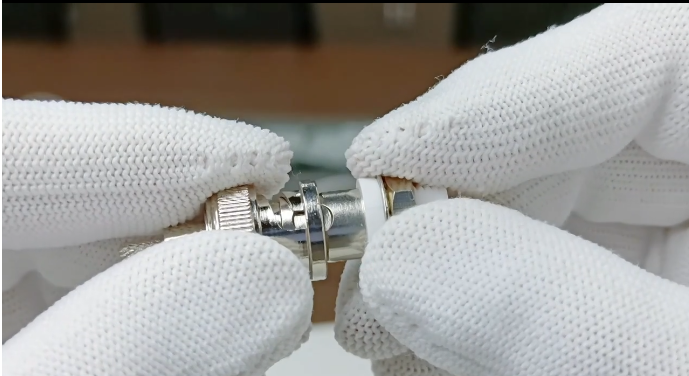

2. Mechanical Reliability: The connector must also provide a secure physical connection. It shouldn't wobble, disconnect easily, or allow environmental factors like moisture to seep in. A physically sound connection is key for a stable signal.

Achieving this level of consistent, reliable transfer demands careful design and manufacturing. Precision-engineered connectors, like those offered by Moco Connectors, are built specifically to meet these tight electrical and mechanical tolerances repeatedly. Their main job is to be the dependable link in your signal chain.

These components are the unsung heroes in loads of different setups. Here are some of the most common places you'll encounter coaxial connectors:

● Home Entertainment: This is where most people know them. Think of connecting your cable box or satellite receiver to the wall outlet or the dish. They're also often the link between your cable modem and the incoming internet line. It's the classic F-type connector you screw onto your TV or set-top box.

● Internet & Networking: Beyond just the modem connection in your house, coaxial cables and their connectors form a big part of the infrastructure delivering high-speed broadband internet to neighborhoods.

● Radio Communications: From amateur radio (Ham) operators linking antennas to their rigs, to CB radios in trucks, and professional two-way radio systems used by emergency services, coaxial connectors provide the essential antenna link.

● Test & Measurement (T&M): In labs and field service, technicians and engineers depend on precise coaxial connections. Equipment like signal generators, spectrum analyzers, oscilloscopes, and network analyzers all use various types of coaxial connectors (like BNC or SMA types) for accurate measurements. Precision is non-negotiable here.

● Broadcasting & Professional AV: Step into a TV studio or a broadcast truck, and you'll see specialized coaxial connectors routing high-frequency video and audio signals between cameras, switchers, and recorders.

While the specific type of connector might change depending on the job (we'll touch on that later), the fundamental need for a secure, reliable connection remains the same across all these areas. Moco Connectors provides a variety of high-performance coaxial connectors designed to meet the demands of these diverse applications, ensuring signal integrity matters most.

Think of it like choosing the right tool for a job. You wouldn't use a hammer to drive a screw. Similarly, using the wrong coaxial connector can lead to a host of problems, ranging from annoying glitches to complete signal failure. They might look similar sometimes, but key differences under the surface matter immensely.

Here’s why the choice is so important:

● Impedance Matching (Again!): We mentioned this before, but it bears repeating. Coaxial systems run at specific impedances, usually 50 Ohms (for RF, data, test gear) or 75 Ohms (mostly for video/TV). Using a 50 Ohm connector in a 75 Ohm system, or vice-versa, creates a mismatch. This causes signal reflections and significant signal loss. It's a fundamental error.

● Frequency Range: Connectors are designed to operate effectively up to a certain frequency. A standard TV connector (F-type) works fine for cable TV frequencies, but will perform poorly or not at all at the much higher frequencies used in some communications or test equipment. You need a connector rated for your operating frequency.

● Physical Type & Connection: There's a whole family of connectors (F-type, BNC, SMA, N-type, TNC, and more). They have different sizes, shapes, and ways of connecting (screw-on, bayonet twist-lock, threaded nut). You simply cannot mate incompatible types. Forcing them will damage the connectors.

● Power Handling: Some applications require the connector to pass DC power along with the signal (like powering an active antenna). The connector must be rated to handle that power safely.

● Environmental Needs: Connectors used outdoors need weather sealing to prevent moisture damage. Connectors in high-vibration settings need robust locking mechanisms.

What happens if you ignore these factors and grab the wrong connector?

● Poor Signal Quality: Pixelation, slow internet, static, dropped calls.

● Intermittent Connections: Signal cutting in and out due to a poor fit or vibration.

● Increased Interference: A poorly shielded or mismatched connector can let noise in.

● Equipment Damage: In rare cases, power mismatches could potentially damage sensitive components.

The bottom line? Always verify the required connector type, impedance, and frequency range for your specific cable and equipment. Don't guess. Finding connectors engineered precisely for your application's demands is key. Suppliers like Moco Connectors offer a range of high-quality options designed to meet these specific electrical and mechanical requirements, helping you make the right choice for reliable performance.

We've seen that coaxial connectors do much more than just physically join a cable to a device. They are engineered components whose primary purpose is to transfer high-frequency signals reliably. This means protecting the signal from outside interference through proper shielding and preventing signal loss by correctly matching the system's impedance.

These connectors show up everywhere – from your living room TV and internet setup to professional radio gear and precision test equipment. While their appearance might change, their core job remains the same: provide a stable, electrically sound pathway for the signal. Remember, choosing the connector that precisely matches your cable type, equipment requirements, and operating frequency is not optional if you want good performance.

So, the next time you're setting up equipment or troubleshooting a fuzzy picture or slow connection, give that small connector a second look. Often overlooked, the quality and suitability of your coaxial connector play a direct role in how well your entire system works. Getting this part right often prevents bigger headaches down the line.

If you need dependable coaxial connectors built for specific electrical and mechanical demands, explore the high-quality options available from Moco Connectors.