SMA connectors are a popular type of RF coaxial connector used in many electronic applications. However, a key question for many engineers and hobbyists is whether SMA connectors are waterproof and can withstand water or moisture exposure.

The short answer is that SMA connectors are not inherently waterproof, but there are waterproof versions available that are designed to withstand harsh environmental conditions. In this article, we will discuss the proper use of SMA connectors in wet environments.

What is an SMA connector?

SMA stands for SuBest wishes, contact us immediately!bMiniature Version A. SMA connectors are threaded coaxial RF connectors that are approximately half the size of standard connectors such as N or F connectors. They are commonly used in radio, wireless and microwave systems where minimizing size and weight is important. Male SMA connectors have a protruding center pin, while female connectors have a housing and a socket that accepts the male pins.

Are SMA connectors waterproof?

Standard SMA connectors are not waterproof and can be easily damaged when exposed to moisture or water. This is because SMA connectors are designed for indoor use and their internal components are not designed to be moisture or waterproof. When exposed to moisture or water, the internal components of SMA connectors can corrode, causing signal loss or complete failure.

However, SMA connectors also come in waterproof versions that can withstand moisture and water. These connectors are typically used in outdoor applications such as telecommunications, marine and industrial protection applications where exposure to moisture or water is common.

When SMA connectors are waterproof

Basic SMA connectors made of stainless steel and other waterproof materials are reasonably waterproof under normal conditions. Brief exposure to moisture or a small splash of water is unlikely to affect most SMA connections as long as they are fully threaded together and intact. However, immersion in water or prolonged exposure to moisture can still penetrate the internal contact areas and damage or corrode the connector. The use of dielectric grease in connectors helps improve water resistance to basic environmental exposure.

Waterproof vs Waterproof SMA

For applications where SMA connectors may be frequently exposed to water or submerged, waterproof SMA connectors are available. These often have additional sealing features such as O-rings or gaskets, and may have a waterproof molded jacket or housing to keep all internal components completely waterproof. These types of sealed, waterproof SMA connectors are necessary for applications such as underwater cameras, marine electronics, and other wet environment equipment. Standard SMA connectors should not be considered waterproof, only potentially waterproof.

In summary, regular SMA coaxial connectors can withstand mild moisture exposure, but for sustained water exposure, a properly waterproof version is necessary. With a range of options available, engineers and designers can select the appropriate SMA connector type based on their required level of waterproofing or waterproofing. Using connectors appropriate for the environment can help ensure reliable performance and avoid damage to equipment and systems.

Best wishes, contact us immediately!

Professionalism: 10 years professional push pull connectors R&D experiences to meet customers’ customized requirements; Excellent sales team, 7/24 help customers to solve their problems.

AUTONOMY: Owned advanced imported production equipment and professional inspection and testing equipment to complete the production and testing independently

Universality: Widely used in the fields of military, medical, audio-video, navigation, measurement, aviation, security, communication and automotive.

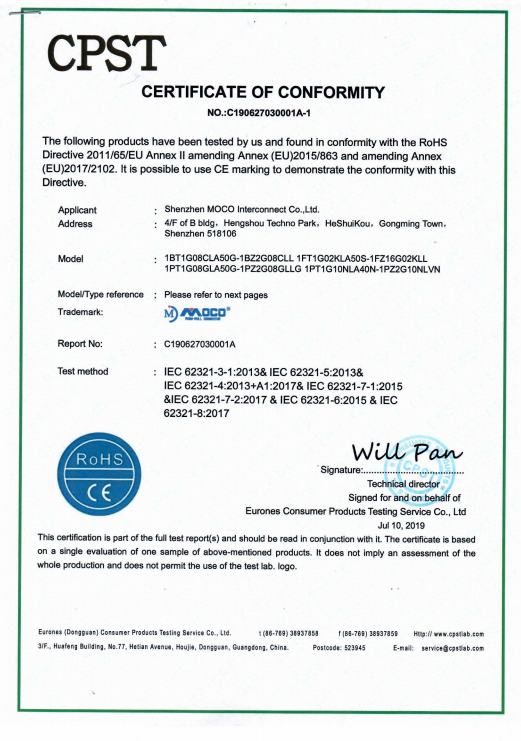

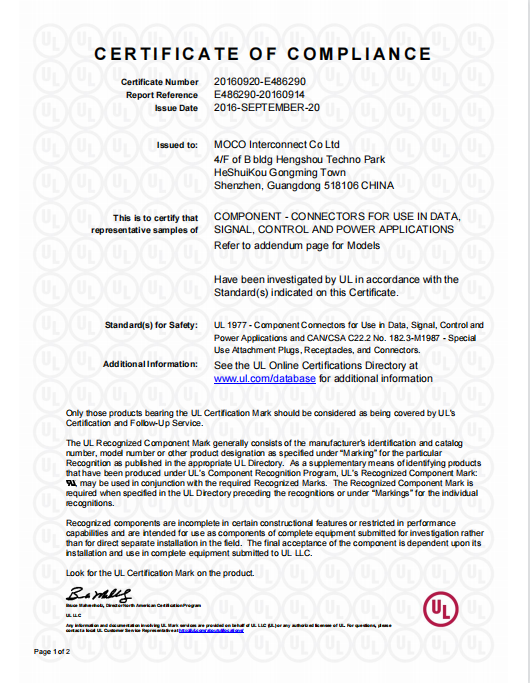

AUTHORITY: Passed GJB9001C-2017, ISO9001:2015, UL, CE and RoHS certifications