The Mighty BNC Connector: What's the Big Deal?

Ah, that BNC connector - a true workhorse in the world of electronics. These little connectors have been around for a long time, and for good reason. They're reliable, easy to use, and have a proven track record of performance. But, like anything in life, there's always a catch. That being the case, the question on everyone's mind is: Do BNC connectors corrode?

Well, before we get into the details, let's take a moment to understand what exactly a BNC connector is, and why it's so important.

BNC stands for Bayonet Neill-Concelman, named after its inventors, Paul Neill and Carl Concelman. These connectors are primarily used to transmit radio frequency (RF) signals, and are commonly found in applications such as video and audio equipment, oscilloscopes, and test instruments.

Now that we understand that, let's get down to the heart of the matter: corrosion.

A Tale of Two Metals: Brass and Corrosion

Brass: The Main Metal in BNC Connectors

Most of the time, BNC connectors are made of brass. Brass is an alloy of copper and zinc, known for its high strength, corrosion resistance, and excellent electrical conductivity. In other words, it's ideal for connectors that need to transmit signals uninterrupted. \n\n### The Reality of Corrosion\n\nSo, do BNC connectors corrode? The short answer is yes, but it's not as simple as it seems. Let's break it down.

Corrosion is the natural process by which a metal breaks down due to a chemical reaction with its environment. The rate at which corrosion occurs depends on a variety of factors, such as the type of metal, the presence of moisture, and surrounding contaminants.

With brass, the main concern is a type of corrosion called dezincification. This process occurs when the zinc in the brass dissolves, leaving behind a porous and weakened copper structure. Over time, this can lead to connector degradation, physical damage, or even complete failure.

Factors Affecting BNC Connector Corrosion

Moisture: The Silent Culprit

As you may have guessed, moisture plays a major role in the corrosion of BNC connectors. Brass is more susceptible to dezincification when exposed to water or high humidity. Therefore, if you use BNC connectors in a humid environment, the risk of corrosion increases significantly.

Contaminants: Adding Fuel to the Fire

Another factor to consider is the presence of contaminants in the environment. Airborne particles such as sulfur and chlorine can accelerate the corrosion process, especially when combined with moisture. If your BNC connectors are used in industrial environments or near the ocean, it is important to keep a close eye on their condition and replace them as needed.

Protection and Prevention: Keep BNC Connectors Corrosion-Free

Protective Coating: A Barrier Against Harsh Weather

One way to protect BNC connectors from corrosion is with a protective coating. Nickel or gold plating can provide an extra layer of defense against the elements, reducing the risk of corrosion. When choosing BNC connectors, look for connectors with high-quality plating to ensure long-lasting performance.

Proper Handling and Storage: Don’t Let Corrosion Catch You Off Guard

Another factor in preventing corrosion is the way you handle and store your BNC connectors. When not in use, store them in a cool, dry place out of direct sunlight. Also, avoid touching the connector pins with your fingers, as oils and moisture from your skin can cause corrosion.

Regular Maintenance: An ounce of prevention is worth a pound of cure

Finally, regular maintenance is key to keeping your BNC connectors in tip-top shape. Check them regularly for signs of corrosion and clean them with a soft, lint-free cloth when necessary. If you notice any noticeable damage or wear, it’s best to replace the connector entirely to ensure optimal performance.

Summary: BNC Connectors and the Battle Against Corrosion

So, can BNC connectors corrode? Yes, they can. But with proper care, handling, and a few preventative measures, you can greatly reduce the risk of corrosion and extend the life of your connectors. By understanding the factors that cause corrosion and taking steps to protect your BNC connectors, you can enjoy the reliable performance they’re known for without any unexpected issues.

Contact us now, best wishes!

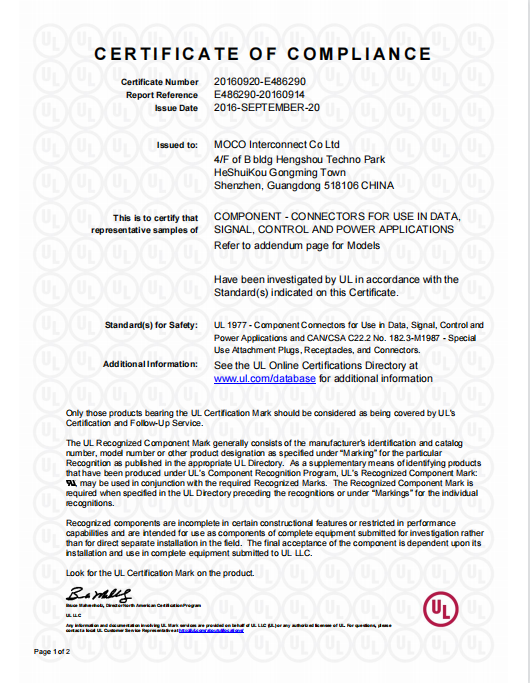

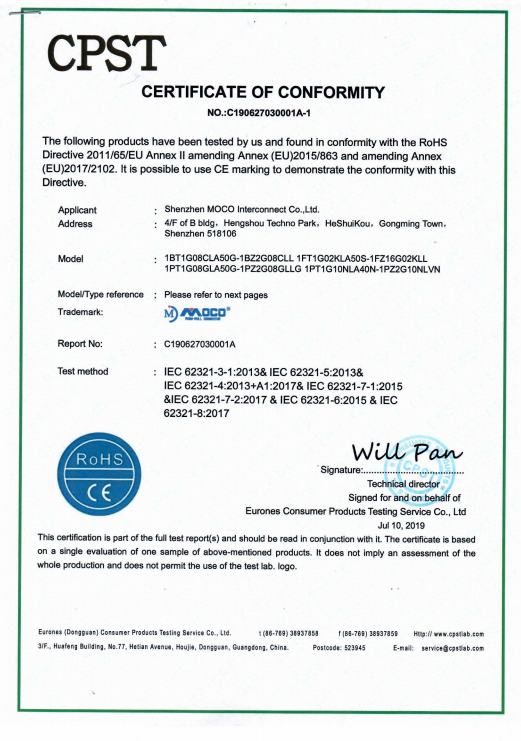

AUTHORITY: Passed GJB9001C-2017, ISO9001:2015, UL, CE and RoHS certifications

Flexibility: Quickly and flexibility response for customer requirements and market changes. Universal model are rich in stock to achieve fast delivery.

AUTONOMY: Owned advanced imported production equipment and professional inspection and testing equipment to complete the production and testing independently

Professionalism: 10 years professional push pull connectors R&D experiences to meet customers’ customized requirements; Excellent sales team, 7/24 help customers to solve their problems.