Waterproof connectors are well-known excellent products. They are used in many fields. So what are their performances that support the market? They are mechanical performance, electrical performance and environmental performance, which help them maintain their market advantages and make them stand out from similar products.

1. Heat resistance.

Today, waterproof connectors have good adaptability at both high and low temperatures. The highest temperature can reach 200 ℃ (except for a few high-temperature dedicated waterproof connectors) and the lowest temperature can be as low as -65 ℃. As we all know . Due to resistance, the equipment will generate a lot of heat when it is powered on. Cause the equipment to heat up. So the temperature we usually mention includes ambient temperature and contact temperature. We will show the maximum temperature limit of the waterproof connector under the rated working current.

2. Waterproof connectors can effectively adapt to salt spray resistant environments.

For general structural metals, electrochemical corrosion may occur on the contact surface. Although we cannot avoid salt and humid working environments. We can improve the performance of waterproof connectors to prevent equipment from being corroded. We test the performance of connectors through smoke tests. Including using a certain concentration of NaCl compressed air to create a smoke atmosphere, general waterproof connectors can reach 48 hours.

3. Vibration resistance and impact resistance are important parameters of waterproof connectors.

These two parameters are particularly important in special environments. Including aviation, aerospace, railways, road transportation, etc. These two parameters are a measure of robustness and electrical contact performance. Usually in impact experiments. Peak acceleration, duration and impact pulsation waveform and time of electrical connection interruption.

Electrical performance is the basic performance of waterproof connectors, generally speaking, including contact resistance, insulation resistance, dielectric strength, etc.

MOCO is a professional connector sales platform with 12 years of experience in the industry. It mainly sells RF coaxial connectors, push-pull connectors, military aviation connectors, etc. Our products are widely used in military aerospace, commercial aviation, industrial applications, medical and other fields.

If you have any questions, please feel free to contact us.

Flexibility: Quickly and flexibility response for customer requirements and market changes. Universal model are rich in stock to achieve fast delivery.

Universality: Widely used in the fields of military, medical, audio-video, navigation, measurement, aviation, security, communication and automotive.

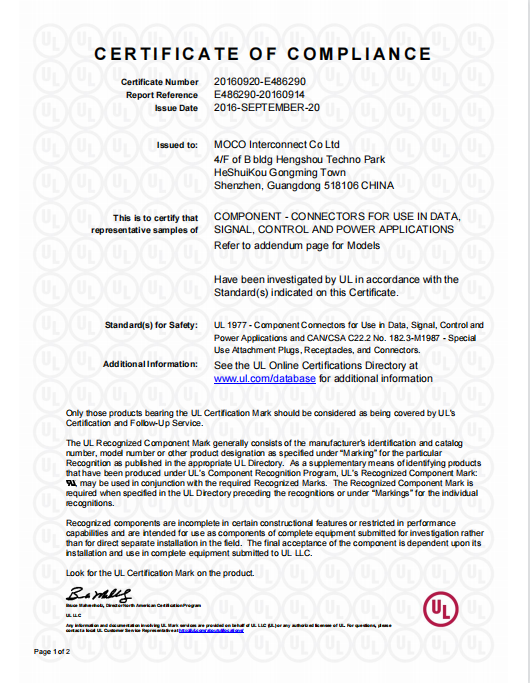

AUTHORITY: Passed GJB9001C-2017, ISO9001:2015, UL, CE and RoHS certifications

AUTONOMY: Owned advanced imported production equipment and professional inspection and testing equipment to complete the production and testing independently