Shenzhen MOCO Interconnect Co., Ltd, is a leading manufacturer & supplier of electrical cable and electrical connector. We have the experience of exporting electrical products to the world.We have nearly a decade experience of developing, designing and manufacturing push pull connectors. With a number of authoritative patents,MOCO can supply eco-friendly qualitied and cable assmbly solutions for you.

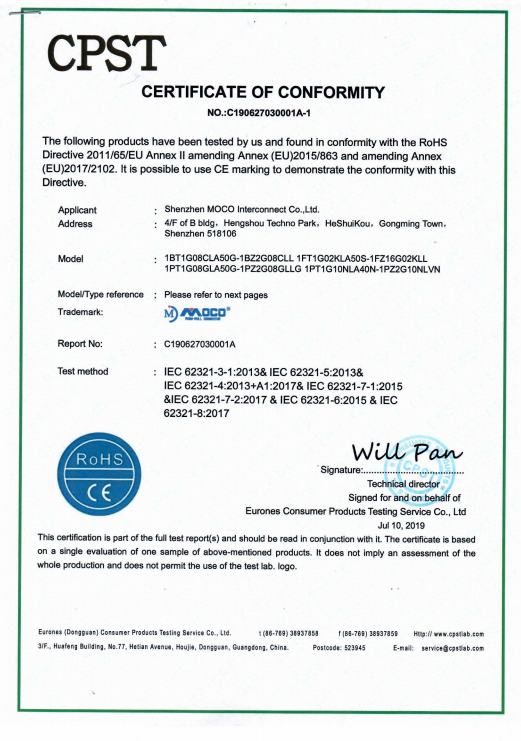

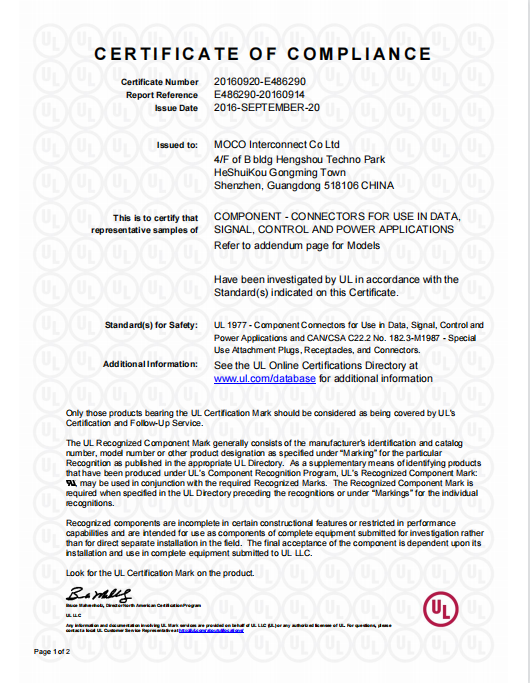

Under the excellent management and great efforts of innovation for many years by MOCO team, we have developed a lot of popular products such as push pull connectors and military connector.MOCO connectors are of stable performance and attractive appearance which are interchangeable with international brands, widely used in the fields measurement, medical, audio-video, military, navigation, scurity, aviation,industrial control, automotive and power etc.We have got 10 utility patents, 2 trade mark and 8 design patents, and passed UL,CE,RoHS and ISO9001:2015 certification. MOCO provides professional technology and service quarantee for your choice.

A military connector (MIL-SPEC) is a shell-type connector that is designed according to military specifications. Their design takes into account the need to protect the connection from environmental factors, so they can be used in military and aerospace applications. In the modern world, the type AN (Army-Navy) connector sets the standard. Many people refer to them as Military Standard, Military Standard, or Military Specific. Many military specifications cover a particular connector type to meet harsh environmental factors. Four common military electrical connectors standards are MIL-DTL-38999, MIL-DTL-26482, mil-dtl-5015 connectors, and MIL-DTL-26500.Commercial and military threaded circular connectors with solderable or crimped contacts are described in MIL-DTL-5015 (formerly MIL-C-5015). Due to their versatility, reliability, and ease of supply, they are commonly used in electronics, electrical power, and control circuits.

Choosing Your MIL-SPEC Connector

You need to have a few basic things in mind when you're choosing your MIL-SPEC connectors. Product parameters to take into account include the number, type, size and coupling method of the contacts, the shell specifications, and the terminals.

CONTACTS

The number of contacts defines how many conductive elements are present in a MIL-SPEC connector. They provide the electrical path when the connection is formed between the two types of contacts, either pins or sockets. AWG (American Wire Gauge) measurements are used to define the contact sizes. There are several different types of coupling available.

Threaded coupling engages the screw threads on the mating connectors.

Bayonet coupling provides fast locking and jacking capability but with limited rotation. It provides constant impedance and is commonly used for network or video transmission via coaxial cables.

Breech lock coupling has a removable locking ring that can join the components together safely and be dismantled easily for cleaning and maintenance.

Quick connect/spring rack coupling is used in a wide range of industries for corrosive liquid flow applications.

Ball detent coupling is a self-locking, quick push-pull coupling that can protect rotating elements from damage due to overloading.

CONNECTOR SHELLS

The main housing for the connector is usually called the shell, often made of aluminium which has been anodised or plated for protection against corrosion. Shell housings are available in various styles, including:

Straight or angled plug

In-line or cable receptacle

Wall or box-mount receptacle

Dummy receptacle

Jam nut receptacle

Solder or weld-mount receptacle

Through-bulkhead receptacle

The standard military style electrical connectors shells range from size 8 (0.50") to size 36 (2.25"), increasing in diameter in increments of 0.0625". Circular MIL-SPEC connectors have cylindrical shells that come in incremental diameter sizes starting at about 0.375". The backshells of MIL-SPEC connectors are usually equal in size to the connector shell or within 0.062" of its diameter.

There are two types of connector shells: male and female. Male connectors can be moved and are usually attached to removable subassembly cables. In order to connect to a circuit, it is inserted into a female connector, which can be a jack, receptacle or other outlet.

TERMINALS

Terminals are used to form electrical connections, and there are several varieties of simple terminal device, such as screws, lugs, cage clamps, wires soldered directly onto a printed circuit board (PCB), quick-connect tabs and crimping. More complex terminals involve inserting connectors into a solder cup or terminal before soldering it to another metal surface; or making a connection with an insulation displacement connector (IDC) by slicing through cable insulation on flat cables. Terminal hole technology (THT) involves the mounting of components on PCBs by pushing them through the board's holes. Quick-disconnect lanyard release terminals can also be used, while solderless electrical connections can be made with a wrapping tool that wraps wire around a terminal post.

MOCO Connectors has widely range of connectors and cables, like push pull circular connectors, sensor connectors, RF connectors, Mil spec connectors, sensor cables, RF cables, camera cables, NDT cables and bare cables, so makes our connectors and cables widely used in aviation, testing, GPS, communication, medical, military and automation instruments.If you need help for your project about connectors and cables, we will tray our best to help you, as we have strong and experience sales team and engineer team. It will save your time and costs once you find a reliable partner.